Boaters, let’s talk plumbing. Specifically, the intricate yet essential network that keeps your vessel running smoothly and your catch alive: your Livewell, Bilge, and Freshwater System Plumbing Diagrams. Mastering these isn't just about avoiding a soggy deck; it's about optimizing your boat's performance, ensuring safety, and extending your time on the water.

This isn't a dry technical manual. Think of it as your seasoned mentor walking you through the critical arteries and veins of your boat's water systems. We'll demystify the diagrams, helping you understand not just what each component does, but why it's there and how it contributes to a seamless boating experience.

At a Glance: What You’ll Discover

- Livewell Wisdom: How to design and troubleshoot systems that keep your bait lively and your prize catch thriving.

- Bilge Basics: Understanding the critical role of bilge pumps and how to prevent your boat from becoming a submarine.

- Freshwater Finesse: Setting up reliable potable water for comfort and convenience on board.

- Decoding Diagrams: Why these technical drawings are your best friend for installation, maintenance, and emergency fixes.

- Smart Upgrades: Tips for optimizing your current setup for better flow, efficiency, and longevity.

The Unsung Heroes: Why Diagrams Matter More Than You Think

Imagine trying to build a house without blueprints, or navigate a complex city without a map. That's essentially what you're doing when you approach your boat's plumbing without proper diagrams. These aren't just pretty pictures; they're the architectural plans of your vessel's liquid lifeblood.

Livewell, bilge, and freshwater system plumbing diagrams are critical for everything from the initial design and installation by boatbuilders to routine maintenance by marine mechanics and troubleshooting by you, the boat owner. They illustrate the exact layout, component connections, and flow paths, making them indispensable for:

- Design & Planning: Ensuring proper system sizing, component compatibility, and efficient routing.

- Installation Guidance: Providing clear, step-by-step instructions for connecting pipes, pumps, and fittings correctly.

- Troubleshooting & Repair: Quickly pinpointing blockages, leaks, or component failures when something goes wrong. An underpowered livewell pump or a clogged bilge drain becomes a much easier fix with a clear visual guide.

- Maintenance: Guiding tasks like cleaning strainers, replacing pumps, or inspecting hose integrity.

Without a diagram, you're guessing. With one, you're operating with precision and confidence, saving time, money, and a lot of headaches.

Livewell Systems: Keeping Your Catch Alive and Kicking

A livewell isn't just a bucket of water; it's a carefully engineered mini-ecosystem designed to maintain the vitality of your bait or your prize fish. The goal is constant fresh water flow, optimal oxygenation, and efficient waste removal. Getting this right means more successful fishing trips and healthier fish.

Core Components of a Thriving Livewell

Before we dive into diagrams, let's break down the essential pieces that make a livewell sing:

- Livewell Tank: This is where the fish reside. Its size needs to match the volume and number of fish you intend to hold, and the material (often roto-molded polyethylene or fiberglass) should be smooth to prevent injury to the fish.

- Pump: The heart of the system, circulating water. Its power must be adequate for the tank's gallon capacity and the number of livewells you're running. A good rule of thumb is to turn over the water in the livewell at least every 5-10 minutes.

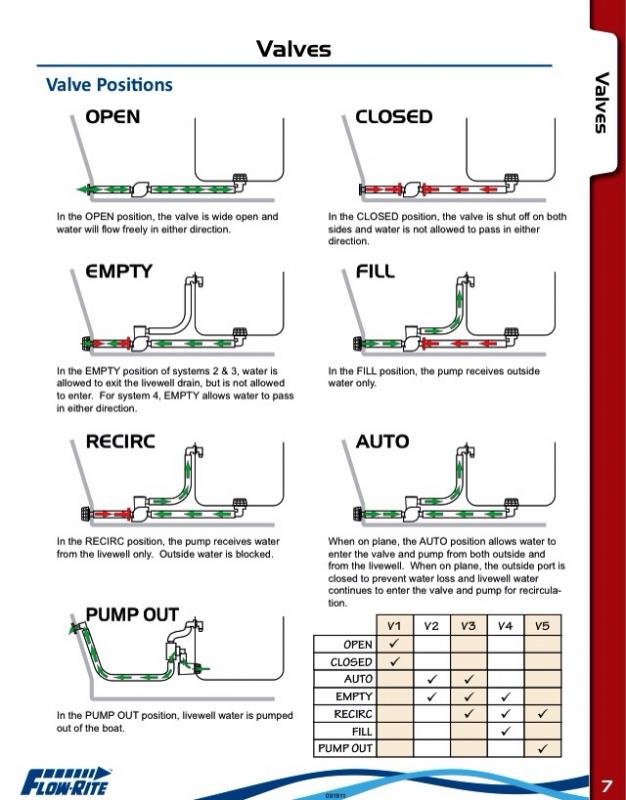

- Intake & Outflow Valves: These regulate water entry and exit, crucial for maintaining a continuous flow and proper water level. You need to be able to adjust them to refresh the water without overfilling or draining too quickly.

- Aeration System: Supplies vital oxygen to the water. This can be via a spray bar, an adjustable aerator nozzle, or even an air pump and diffuser stone. The capacity must match the biological load (i.e., the number of fish).

Common Livewell Plumbing Setups: A Diagrammatic Deep Dive

The way water enters, circulates, and exits your livewell defines its efficiency. Here are three common setups, each with its own advantages, best uses, and typical fittings.

1. Overflow Ties into the Drain Line

- Mechanism: This setup is clever for space-saving. The livewell's overflow "T's" directly into the main drain line. This allows for continuous water refresh (new water in, old water out) while recirculating some of the water.

- Best For: Side-mount livewells or situations where you want to avoid drilling additional holes in your boat's hull above the waterline.

- Installation Nuances: This often means a single thru-hull for the drain that handles both overflow and eventual complete tank draining.

- Typical Fittings You'll See on the Diagram:

- 1-1/8" elbow thru-hulls with screen (for the livewell overflow).

- 1-1/8" straight thru-hull (for the transom drain outlet).

- 1-1/8" "T" fitting (to merge the overflow and drain lines).

- Adjustable aerator nozzle (for oxygenation).

- 1-1/8" I.D. hose (connecting the overflow to the "T" and the "T" to the transom drain).

- 3/4" drain fitting with a 3/4" to 1-1/8" adapter (if the tank drain itself is smaller).

2. Stand Pipe Overflow Threads into the Drain Fitting

- Mechanism: This is a remarkably simple and effective design, especially for smaller bait wells. A standpipe, which can be threaded or a push-in style, is inserted into the main drain fitting at the bottom of the livewell. The height of the standpipe dictates the water level. Water then freshens by flowing over the top of the standpipe and out the drain, while still allowing for recirculation. To drain the livewell completely, you simply remove the standpipe.

- Best For: Bait wells where simplicity and ease of draining are key. It's also great for avoiding extra hull penetrations.

- Installation Nuances: Minimal drilling in the livewell itself, as the standpipe utilizes the existing drain.

- Typical Fittings You'll See on the Diagram:

- 1-1/8" threaded thru-hulls with a screened threaded overflow tube (this is the standpipe assembly).

- 1-1/8" straight thru-hull (for the transom drain).

- Adjustable aerator nozzle.

- 1-1/8" I.D. hose (connecting the livewell drain to the transom drain).

3. Overflow Directly Out the Top Side of the Tank

- Mechanism: This setup is straightforward. The livewell has a dedicated overflow outlet positioned high on its side. Water flows into the livewell, and once it reaches the overflow level, it exits directly through this separate outlet, typically routed through the boat hull above the waterline. This ensures continuous water refresh and recirculation.

- Best For: Horizontal mount livewells where an above-waterline hull penetration is acceptable and desirable for direct drainage.

- Installation Nuances: Often considered the easiest to install, as the overflow path is direct and doesn't rely on merging with other drain lines.

- Typical Fittings You'll See on the Diagram:

- 1-1/8" straight thru-hulls with screen (for the tank's dedicated side overflow).

- 1-1/8" straight thru-hull (for the above-waterline transom or hull outlet).

- 1-1/8" I.D. hose (connecting the tank overflow to the hull outlet).

- Adjustable aerator nozzle.

- Two 3/4" drain thru-hulls (one for the tank's complete drain, one for its transom outlet).

- 3/4" I.D. hose (connecting the tank drain to its transom outlet).

Pro Tip: Remember, pump size always depends on the livewell's gallon capacity and the number of livewells or bait wells installed. Don't skimp here; an underpowered pump is a dead bait bucket. Expert assistance is often available for designing or troubleshooting livewell systems, especially if you're building a custom setup or dealing with persistent issues.

Bilge Systems: Your Boat's Last Line of Defense

While livewells keep your fish happy, bilge systems keep you afloat. The bilge is the lowest part of your boat's hull, and it's where any stray water – from splashes, leaks, or rain – collects. A properly designed and maintained bilge system is absolutely critical for safety.

The Anatomy of a Bilge System

A simple bilge system has fewer moving parts than a livewell, but each is vital:

- Bilge Pump(s): The workhorse. These submersible pumps activate to remove water from the bilge. They come in various capacities (measured in gallons per hour, GPH), and often a boat will have multiple pumps: a smaller, primary pump and a larger, emergency backup.

- Float Switch: The brains of an automatic bilge pump. This switch detects rising water levels in the bilge and automatically turns the pump on. Some pumps have integrated float switches.

- Hosing (Discharge Hose): Carries the water from the pump to the thru-hull fitting. It should be robust, kink-resistant, and correctly sized for the pump's output to prevent backpressure.

- Thru-Hull Fitting: The outlet where water is discharged from the boat, typically above the waterline. It should have a check valve or be positioned high enough to prevent backflow.

- Strainer/Filter: Prevents debris (like hair, fishing line, or loose screws) from entering and clogging the pump impeller.

Common Bilge Plumbing Diagrams

Bilge diagrams tend to be simpler, focusing on pump placement and discharge routing.

Single Automatic Bilge Pump

- Mechanism: A single submersible bilge pump, typically wired to a float switch and a manual override switch at the helm. When water rises, the float switch activates the pump, discharging water overboard.

- Best For: Smaller boats or as a primary pump in conjunction with a larger secondary pump.

- Diagram Insights: You'll see the pump at the lowest point of the bilge, connected via hosing to a thru-hull fitting above the waterline. The wiring diagram will show connections to the battery, float switch, and helm switch.

Multiple Bilge Pumps (Primary & Secondary)

- Mechanism: Larger boats often have at least two pumps: a smaller GPH pump (e.g., 500 GPH) for routine water removal, and a much larger GPH pump (e.g., 2000 GPH) positioned slightly higher, acting as an emergency pump. Each typically has its own float switch, wired independently for redundancy.

- Best For: Any boat over 20 feet, or boats that venture offshore, requiring enhanced safety.

- Diagram Insights: Clearly shows two (or more) pumps, their respective float switch positions, and separate discharge lines or a merged line with proper check valves to prevent water from flowing back into the bilge through an inactive pump. The wiring will be more complex, showing independent circuits and helm switches for each.

Manual Back-up Pump

- Mechanism: In addition to electric pumps, some diagrams might show a manual hand pump system, often with a long hose that can be dropped into the bilge, or a fixed pump with a selector valve to draw from different bilge compartments.

- Best For: Essential redundancy for any serious boater, especially where battery power might fail.

- Diagram Insights: Illustrates the manual pump's location, intake hose routing, and discharge path.

Critical Considerations for Bilge Diagrams: - Pump Sizing: Ensure pump capacity is adequate for your boat's volume and potential water ingress scenarios.

- Hose Routing: Keep hoses as straight and short as possible with minimal bends to maximize flow and prevent airlocks.

- Check Valves: While tempting to prevent backflow, check valves can clog and fail. Many experts prefer to route discharge hoses to rise continuously from the pump to the thru-hull, creating a natural anti-siphon loop, or to use an open-ended thru-hull positioned well above the waterline. If check valves are used, they must be accessible for inspection and cleaning.

- Wiring: Bilge pumps are often hardwired directly to the battery with in-line fuses, allowing them to operate even if the main power switch is off. This crucial detail will be prominent in the wiring overlay on your plumbing diagram.

Freshwater Systems: Comfort and Convenience on Deck

Your boat's freshwater system brings the comforts of home to the open water, from a refreshing shower after a swim to potable water for cooking and cleaning. Understanding its plumbing diagram ensures you have a reliable supply when you need it most.

Key Components of Your Potable Water Supply

- Freshwater Tank(s): Stores your potable water. Tanks vary in size and material (often plastic or aluminum) and must be kept clean to prevent bacterial growth.

- Freshwater Pump: Typically a 12V diaphragm pump, it creates pressure in the system, delivering water to various outlets. It usually has an integrated pressure switch that turns the pump on when pressure drops (e.g., a faucet opens) and off when pressure is restored.

- Accumulator Tank (Optional but Recommended): A small pressure tank that works with the pump to smooth out water flow and reduce pump cycling, extending pump life and providing a more consistent stream.

- Water Heater (Optional): If your boat has hot water, a water heater (often engine-heated or shore power electric) will be part of the system.

- Faucets & Shower Heads: Your water outlets.

- Fill Port & Vent: The fill port allows you to add water to the tank, and a vent prevents airlocks during filling and allows air in/out during use.

- Hosing: Food-grade, reinforced hose is essential for potable water systems to prevent contamination and maintain structural integrity.

Typical Freshwater Plumbing Diagram Sections

Freshwater diagrams are often more complex due to multiple outlets and optional components.

Basic Freshwater System

- Mechanism: Water flows from the tank, through the pump (and optional accumulator), and branches off to various cold water outlets like galley faucets or washdown spigots.

- Diagram Insights: Shows the tank location, pump placement (often near the tank), and main trunk line with smaller lines branching off to each fixture. You'll see shut-off valves for individual lines, which are critical for isolating leaks or servicing specific components.

Hot & Cold Freshwater System

- Mechanism: Similar to the basic system, but after the pump, a main cold water line also feeds into a water heater. The heated water then returns via a separate hot water line, which runs parallel to the cold line, supplying hot water to designated fixtures.

- Diagram Insights: This will clearly delineate cold (often blue lines) and hot (often red lines) water paths. It will show the water heater's location, its connections to the cold water supply, and its own hot water output line. Bypass valves around the water heater are common for winterization.

Freshwater Washdown System

- Mechanism: Often a dedicated pump (or sometimes fed from the main freshwater system with a diverter valve) that supplies a high-pressure nozzle for rinsing decks, anchor rodes, or gear.

- Diagram Insights: Shows the washdown pump (if separate), its intake (from the main freshwater tank or sometimes a separate washdown tank), and the hose routing to the spigot.

Key Design Principles for Freshwater Plumbing: - Accessibility: All components – especially pumps, filters, and shut-off valves – should be easily accessible for maintenance.

- Line Protection: Protect hoses from chafing, heat, and sharp objects.

- Winterization: Ensure the system is designed with drain points and bypasses (especially for water heaters) to facilitate easy winterization and prevent freeze damage.

- Sanitation: Diagrams can help identify all points in the system, ensuring proper flushing and sanitation procedures are followed regularly to maintain water quality.

For a deeper dive into how marine systems are laid out, you might find it useful to view 2006 NauticStar 205 DC schematics, which provide a real-world example of how these various systems are integrated into a complete boat design.

Troubleshooting Common Plumbing Headaches

Even with the best diagrams, issues can arise. Here’s how your knowledge of these systems and their diagrams can turn you into a plumbing pro:

- No Water Flow (Freshwater/Livewell):

- Diagram Check: Trace the line from the pump. Is there a shut-off valve accidentally closed? Is the intake seacock closed?

- Physical Check: Is the pump strainer clear? Is the pump running but simply cavitating (sucking air due to low water)? Is there power to the pump?

- Weak Flow (Freshwater/Livewell):

- Diagram Check: Look for small diameter hoses or too many sharp bends – these restrict flow.

- Physical Check: Partially clogged strainer or aerator nozzle. A failing pump. Low voltage to the pump.

- Pump Runs Constantly (Freshwater):

- Diagram Check: Is there a leak in the system that's causing pressure loss? Look for all connection points.

- Physical Check: A leaking faucet or shower head. A loose hose clamp. A faulty pressure switch on the pump (or the accumulator needs recharging).

- Bilge Pump Not Activating:

- Diagram Check: Trace the wiring. Is the fuse blown? Is the float switch connected correctly?

- Physical Check: Stuck float switch (often due to debris). No power to the pump. Clogged intake strainer.

- Bilge Pump Runs But No Water:

- Diagram Check: Confirm the discharge hose routing.

- Physical Check: Airlock in the hose. Clogged discharge thru-hull. Disconnected hose from the pump.

The Golden Rule: Always start with the simplest explanation. Is it plugged in? Is the valve open? Is the fuse good? Then, use your plumbing diagram to systematically trace the problem.

Optimizing Your Boat's Plumbing for Peak Performance

Beyond just fixing problems, understanding your diagrams empowers you to make smart upgrades and improvements.

- Hose Upgrades: Replace old, cracked, or undersized hoses with marine-grade, reinforced, and properly sized alternatives. Use stainless steel hose clamps, doubled up below the waterline.

- Pump Sizing: If your livewell or bilge pump struggles, consult your diagram and consider upgrading to a higher GPH pump. For livewells, match pump size to tank volume for optimal water turnover.

- Filtration: Add or improve strainers on livewell intakes and freshwater lines. A clean strainer is a happy pump.

- Accessibility: If your diagrams reveal components buried in impossible-to-reach spots, consider relocating them or adding access panels during your next refit. Future you will thank current you.

- Valves & Seacocks: Regularly inspect and exercise all seacocks and inline valves. Ensure they operate smoothly and are clearly labeled on your diagram. Consider adding emergency plugs near thru-hulls.

- Redundancy: For critical systems like the bilge, always aim for redundancy. Two pumps are better than one, and a manual backup is peace of mind.

- Labels: Take your diagrams a step further and physically label all pumps, valves, and thru-hulls on your boat to match the diagram. This makes troubleshooting incredibly fast.

Beyond the Blueprint: Taking Action

You now have a clearer understanding of your boat's livewell, bilge, and freshwater systems, and more importantly, how their plumbing diagrams are your most valuable tool. These aren't just lines on a page; they're the blueprint to your boat's health and your enjoyment on the water.

Take the time to locate the plumbing diagrams for your specific vessel. If you don't have them, consider creating your own simple sketches. Start with your livewell: trace the intake, pump, overflow, and drain. Do the same for your bilge pumps and freshwater tank. This act of mapping will build your intimate knowledge of your boat's systems, empowering you to perform routine maintenance, troubleshoot with confidence, and make informed decisions about upgrades.

Whether you're preventing a fish-kill, a bilge-pump failure, or just a dry faucet, understanding these critical systems is fundamental to responsible boat ownership. Go forth, examine those diagrams, and keep your boat's liquid heart beating strong!